KOMPSAT-3 – Optical Ground Support Equipment

Designed and manufactured to test the optical telescope also manufactured by TSESO in ambient and vacuum conditions. A 9 meter support bench with a 1 meter diameter collimator and a 1 meter diameter mototrized mirror for autocollimation were the main pieces.

Designed and manufactured to test the optical telescope also manufactured by TSESO in ambient and vacuum conditions. A 9 meter support bench with a 1 meter diameter collimator and a 1 meter diameter mototrized mirror for autocollimation were the main pieces.

A complex multidisciplinary project

Here is a list of the main systems to be provided:

– A 9 meter optical bench

– A large Cassegrain Collimator for optical testing purpose

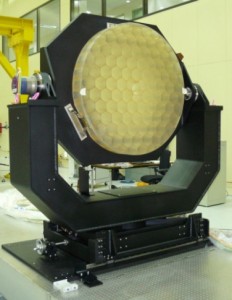

– A 1 meter diameter and motorized auto-collimation mirror

– Motorized payload support system

– Focal plane instruments (motorized stages, integrating sphere, filters, monochromator)

– Air cushioned conveyor – Optical windows for vacuum chamber

– Vibration free system to protect the optical system

– Temperature monitoring system

– Command/control software for the positioning of the components

Thales SESO Efficiency

It only took 2 years to design, manufacture, test and deliver all the components of this massive project. It was delivered in September 2008

World class performances

2 large mirrors of 1 meter (flat and concave) were made using Zerodur™ ensuring virtually no thermal expension. Extremely low wavefront error (26nm RMS for the collimator and 9nm RMS for the flat auto-collimation) Minimal weight: lightened mirrors up to 80% its original weight

Results in the most modern optical laboratory in Asia

KOMPSAT-3 – Optical Ground Support Equipment

Designed and manufactured to test the optical telescope also manufactured by TSESO in ambient and vacuum conditions. A 9 meter support bench with a 1 meter diameter collimator and a 1 meter diameter mototrized mirror for autocollimation were the main pieces.

Designed and manufactured to test the optical telescope also manufactured by TSESO in ambient and vacuum conditions. A 9 meter support bench with a 1 meter diameter collimator and a 1 meter diameter mototrized mirror for autocollimation were the main pieces.

A complex multidisciplinary project

Here is a list of the main systems to be provided:

– A 9 meter optical bench

– A large Cassegrain Collimator for optical testing purpose

– A 1 meter diameter and motorized auto-collimation mirror

– Motorized payload support system

– Focal plane instruments (motorized stages, integrating sphere, filters, monochromator)

– Air cushioned conveyor – Optical windows for vacuum chamber

– Vibration free system to protect the optical system

– Temperature monitoring system

– Command/control software for the positioning of the components

Thales SESO Efficiency

It only took 2 years to design, manufacture, test and deliver all the components of this massive project. It was delivered in September 2008

World class performances

2 large mirrors of 1 meter (flat and concave) were made using Zerodur™ ensuring virtually no thermal expension. Extremely low wavefront error (26nm RMS for the collimator and 9nm RMS for the flat auto-collimation) Minimal weight: lightened mirrors up to 80% its original weight

Results in the most modern optical laboratory in Asia

[button text=”<< Back to list" link="new-services/test-systems/" style="default" size="normal" target="_self" display="inline" icon="no" class="padding"] [/row]