Our SESO® optics are designed and manufactured to meet the high end, state-of-the-art, challenging requirements or our customers.

A trusted partner

We have been gaining experience for 50 years in the fields of Space, Astronomy, Science, X-Ray and test systems. Our optical systems are mounted on some of the most renowned satellites (ie, Pleiades, Kompsat-3, Spot, Jason, Saral, etc), Synchrotrons (ie, Spring 8, Argonne, ESRF, etc), and Telescopes (ie, VLT, LBT, GTC, etc).

Our customers are all over the world (Asia, Europe, North America, South America, Middle-East and Oceania).

We are the world leaders in the market of bendable X-Ray mirrors for synchrotrons.

We are the number one European manufacturer of large Zerodur™ mirrors for spatial applications.

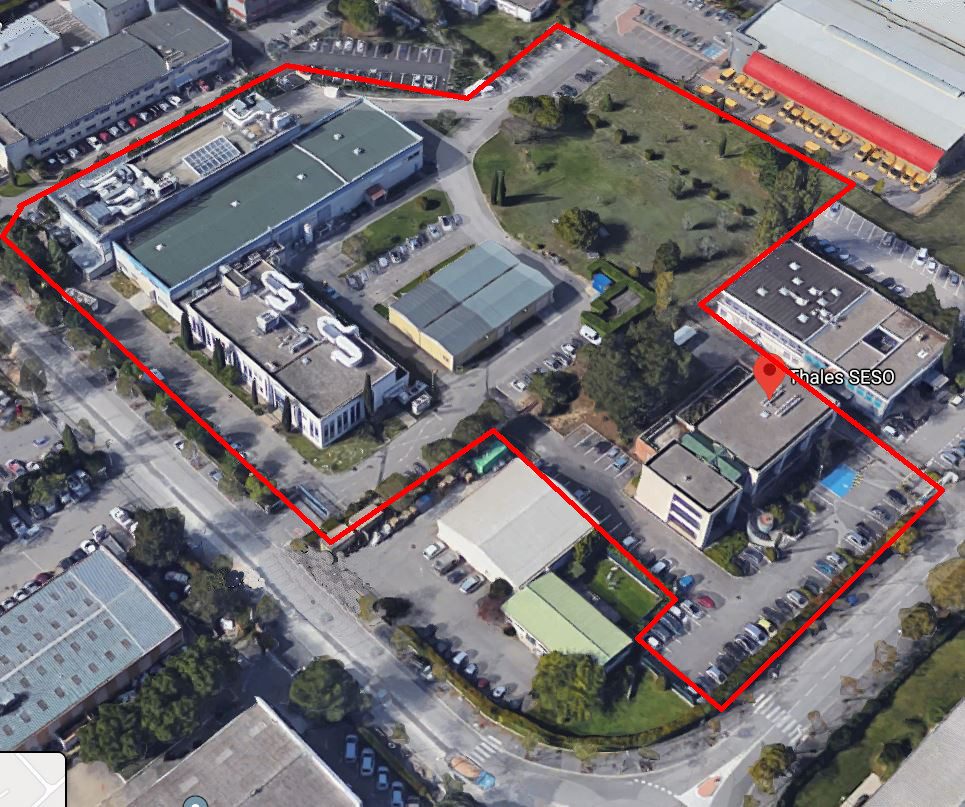

We works in close relationship with Thales Optronics. They provide optronics solutions, including Lasers

World Class Capabilities

We masters internally all the manufacturing steps thanks to an exceptionally wide range of milling, grinding, lightening, polishing and coatings machines and robots (more than 80). It gives us the flexibility to adapt to the most exigent customer specifications.

Shape : spheric, aspheric (elliptic, parabolic, hyperbolic, toroid and higher orders), on-axis or off-axis.

Size : from few cm to 2 meters.

Material : Glasses, Ceramics (Zerodur™, SiC, ULE™), Metals (Al, Cu, Be), Semiconductor (Si, Ge), Crystals (ZnSe, CaF2), and others.

Coating : protected or unprotected with Gold, Cr, Rh, Pt, B4C, Graphite, Al, Ag, oxides (SiO2, Al2O3, …), fluorides (MgF2, BaF2, etc…), selenides, sulfides.

Precision : low Roughness (super polishing down to 1 angström RMS) and tight flatness (few nm RMS/PTV), …

Mirror lightening : up to 85% the original weight of the mirror depending of its size

To guaranty the optics meet the specifications, a wide range of interferometers are used to map the surface to less than 1 angstrom accuracy (more than 10 interferometer benches to adapt every shape, size or application).

We keep innovating and investing

SESO® constant investment and innovation policy ensures we remain competitive by improving roughness, flatness, weight, stability, etc. Among the last investments and innovations, we can count the 2 Magnethoreology robots, an Ion Beam Figuring machine, a double side polishing machine for large flat optics, large and fast interferometers, and a patented deformable mirrors and bender.

Customer support and satisfaction

We are able to provide the best solutions and assist you in the definition of your project. Our staff is mostly composed of engineers, PhDs and qualified technicians, and have an extended experience in opto-mechanical design, simulation, integration and Finite element simulation (for stresses, temperature, vibration, deformation simulation).