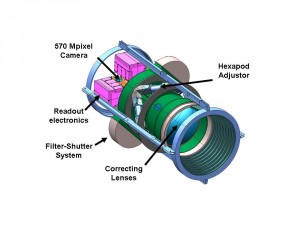

Optical corrector for Dark Energy Survey

THALES SESO was collaborating to The Dark Energy Survey (DES) project project by manufacturing (grinding, polishing, control and coat and AR coatings) the 5 large lenses (up to 1m size, including evenasphere) of this optical corrector.

THALES SESO was collaborating to The Dark Energy Survey (DES) project project by manufacturing (grinding, polishing, control and coat and AR coatings) the 5 large lenses (up to 1m size, including evenasphere) of this optical corrector.

DES is a major ground-based Astronomy project designed to probe the origin of the accelerating universe. To do that, an extremely sensitive high resolution/high field of view camera (DECAM) is mounted at the focal plane of the existing 4m Blanco Telescope (location Cerro Tololo Observatory in Chile).

Change units to metric (or leave both). Give a title. Specifications not impressive for non-opticians

The optical corrector system of the DECam is a Wynn-style five lens solution, with two aspheres design (C2 and C4). It provides a 2.2 degrees field of view image at 0.27″/pixel while contributing less than 0.3″ FWHM to the image quality. The lenses are all made out of Silica. Blanks have been casted by Corning in New York and have been grinded/polished and coated by Thales Seso in France. The biggest of these lenses (i.e. the entrance lens named C1 element) is almost 1m in diameter and has a weight of 380 pounds!

Courtesy of UCL-UK and Fermilab-USA

Key- requirements of these lenses:

| Element | Type | Size | Optical Quality per surface |

| C1 | CX spherical /CV spherical | Φ 980mm | <100nm RMS |

| C2 | CX spherical / CV aspherical | Φ 690mm | <60/250nm RMS (spherical/aspherical sides) |

| C3 | CX spherical /CV spherical | Φ 650mm | <60nm RMS |

| C4 | CX spherical /CV spherical | Φ 600mm | <60/250nm RMS (spherical/aspherical sides) |

| C5 | CX spherical /CV spherical | Φ 550mm | <60nm RMS |

Other optical specifications were almost the following ones:

• Radii tolerances within about +/-0.5mm

• Thickness tolerances within about +/-0.2mm

• Tilts/wedges < 0.05mm

• S/D quality better than 60/40 (relaxed up to 80/50 for the largest C1 element)

• Microroughness better than 2nm RMS